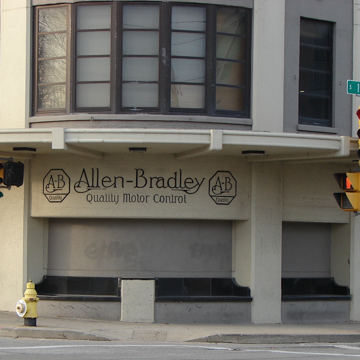

Physician Stanton Allen joined with Lynde and Harry Bradley in 1909 to bring the precision of machine automation to manufacturing industries. Their Compression Rheostat Company became Allen-Bradley in 1910. When Rockwell International purchased Allen-Bradley for $1.685 billion in 1985, the sale marked the largest acquisition in Wisconsin’s history.

Allen-Bradley is a Milwaukee landmark, identifiable by its reputedly world’s largest four-face clock raised on a 333.3-foot-tall tower built in 1962. The U.S. Coast Guard lists the clock tower as an official landmark on its maps of Lake Michigan. Each octagonal clock face is 40.2 feet wide, with timing hands several feet longer than London’s Big Ben. The clock tower and the towers bracketing the office complex have low hipped roofs with wide eaves. The plant grew from its original site in the Pfeiffer and Smith Machine shop on S. 1st Street, expanding into its first major addition at S. 2nd Street and Greenfield Avenue in 1919. The company’s growth matched the popularity of radios controlled by A-B equipment and the use of its solenoids built for the automotive and industrial equipment market. A major addition, built in 1948, added a million square feet of production space to the factory. In 1958, the City of Milwaukee permitted construction of a walkway over S. 2nd Street joining A-B’s research facility to an office research complex and clock tower office building constructed in 1964. Completion of its office buildings, high-voltage research center, and materials-testing laboratories in 1969, all sheathed in a vertically emphasized grid of metal and stucco, creates more than three million square feet in Milwaukee’s best-known industrial design buildings.